Wire preparation

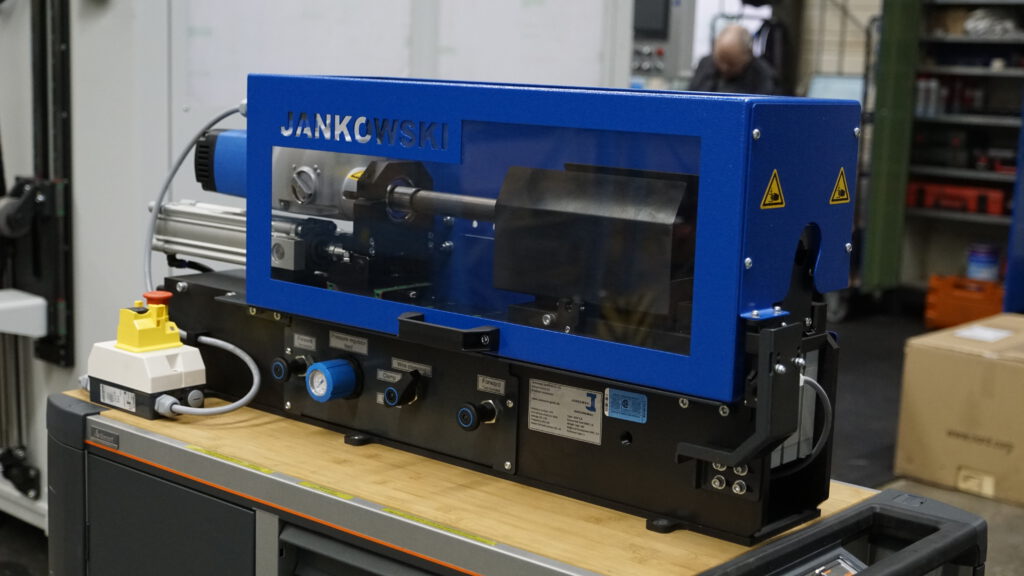

Before starting the drawing process, wire pointing is mandatory. During this process, the pointing tool rotates around the wire and uniformly peels the cross-section down to the required diameter. Depending on the material removal, pointing time using the peeling method typically ranges between 5 and 20 seconds. For smaller wire diameters up to 12 mm, we alternatively offer the rolling method. In this process, the wire is formed between two rotating rolling tools, reducing the wire cross-section in a material-friendly manner.

The wire pointing unit can be flexibly integrated into your system concept. You can choose between direct mounting on a pre-drawing machine or a payoff reel, or a stand-alone version on a mobile carriage – tailored to your individual requirements.

Our wire-preparation-options:

Peeling

During the peeling process, the sharpening tool rotates around the wire and uniformly peels it down to the desired diameter. This process is available for wire diameters ranging from 5.5 mm to 30 mm.

Contact

Do you have any questions about our wire sharpening units?

Our contact persons are available for a personal conversation.