Wire feeder

Tailored to your specific application, we offer a wide range of high-performance solutions for wire feeding. For smaller wire diameters up to 16 mm, the proven non-driven turntable is suitable, while for larger wire diameters a motor-driven turntable or, alternatively, a cantilever payoff reel is available. This ensures reliable and process-safe wire pay-off for a wide variety of requirements.

In addition, we offer modern feed units for precise wire feeding to downstream machines. These can be flexibly combined with straightening units and/or a wire pointing machine, enabling a customized adaptation to your individual production processes – feel free to contact us.

Our wire feed options:

Turntable

For small wire diameters up to 16 mm, the classic non-driven turntable is sufficient. Optionally, the turntable can be equipped with a turntable brake upon customer request. The design is available either with or without a base frame.

Powered turntable

The powered turntable ensures homogeneous and uniform unwinding of the wire coil. This significantly reduces wear on the press tools of the infeed press. The turntable is controlled via a mobile control panel, allowing flexible and user-friendly operation.

Support arm reel

The support arm reel is specifically designed for larger wire diameters in the range of 14 to 30 mm and is suitable for horizontal wire pay-off. Wire feeding is controlled by a contactless speed regulation system, ensuring a uniform and material-friendly unwinding process.

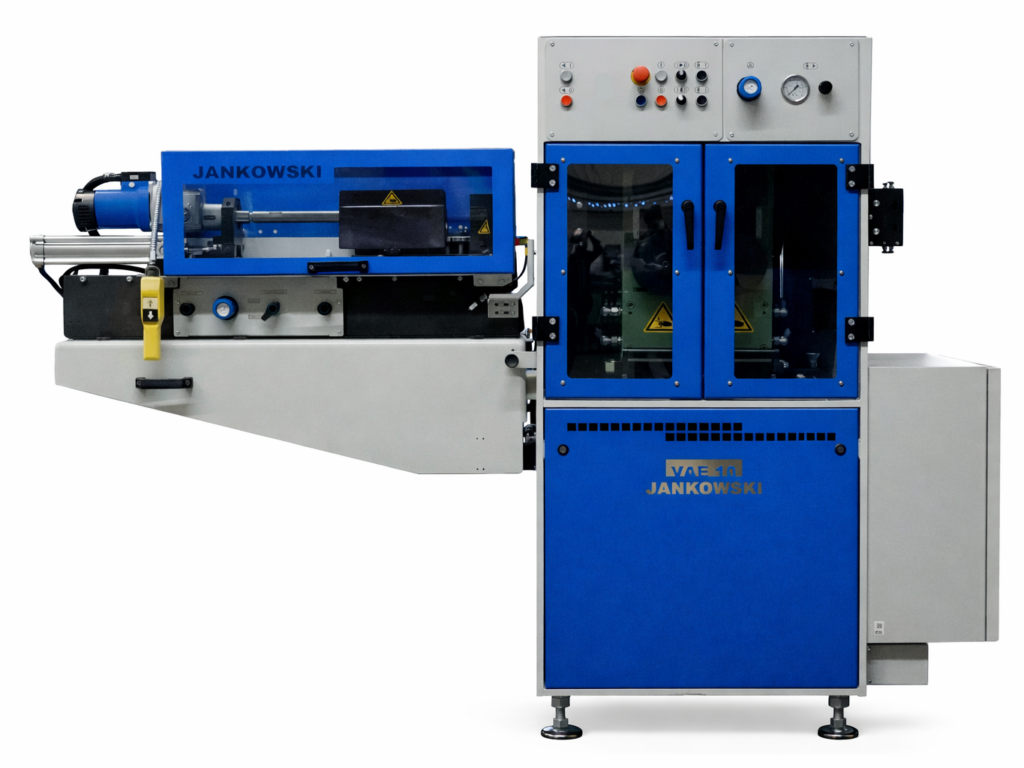

Feed-sharpening-straightening

The feed-sharpening-straightening unit is used for the safe feeding of straightened wire to the downstream machine, for example a forming press. It ensures uniform wire guidance and stable process quality. Depending on the application requirements, flexible combinations of pointing, straightening, and feeding units are possible.

Which wire feeding system is suitable for which application?

The selection of wire feeding options depends on the specific requirements and process-related boundary conditions. For smaller wire diameters up to approximately 16 mm, non-driven turntables are generally sufficient. For larger wire diameters, the use of a motor-driven turntable or, alternatively, a cantilever payoff reel is recommended to ensure reliable and uniform wire pay-off.

In addition, the design of the wire feeding system can be customized to meet individual customer requirements. This includes, among other things, solutions for continuous wire feeding as well as optional pneumatic wire monitoring systems that ensure safe and controlled wire handling.

Contact

Do you have questions about our wire feed options?

Our contact persons are available for a personal conversation.