Wire drawing machines

For more than 25 years, the development, construction and assembly of Inline wire drawing machines from Jankowski GmbH & Co. KG has been part of our great competence and passion. In addition to the construction of high-quality systems, the focus is above all on the tangible user-friendliness and the uncompromising compliance with the applicable occupational safety guidelines according to German and European standards. It is precisely in this area that we as the company Jankowski GmbH & Co KG have found our place and we like to work together with leading international companies whose objective, in accordance with ours, is to operate in the long term and sustainably in Europe according to the highest standards.

Our drawing machine series:

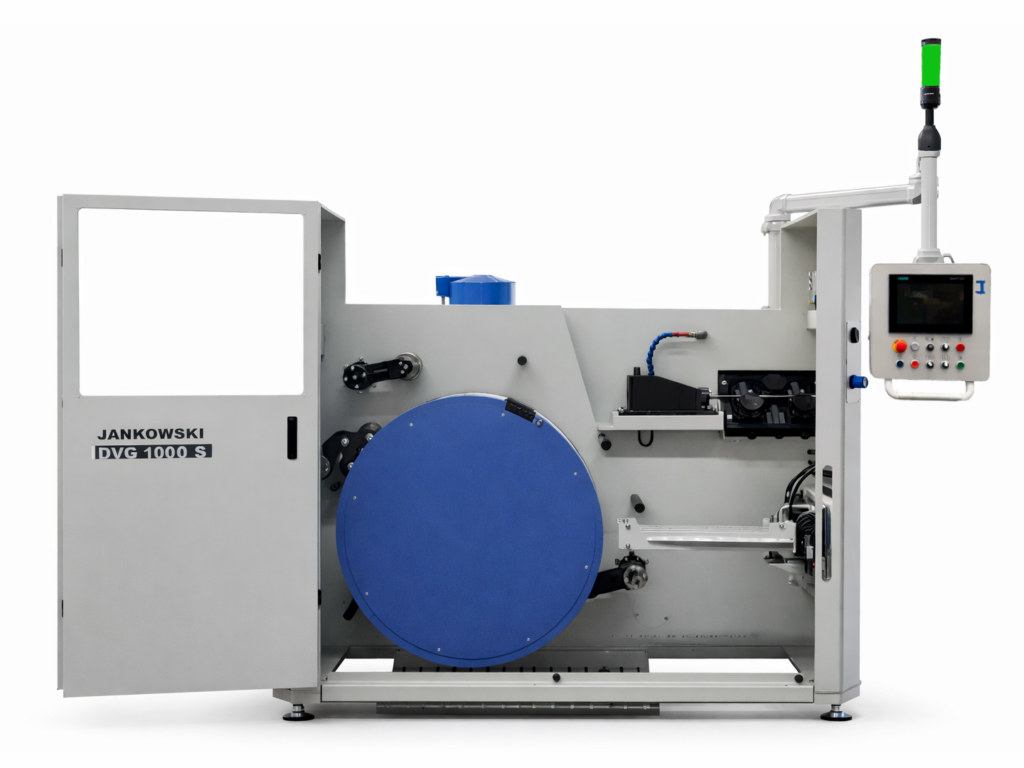

ECO-Series

The ECO-Series combines simple, user-friendly operation with a standard high-efficiency synchronous motor and is specifically designed for the reliable processing of thin wires.

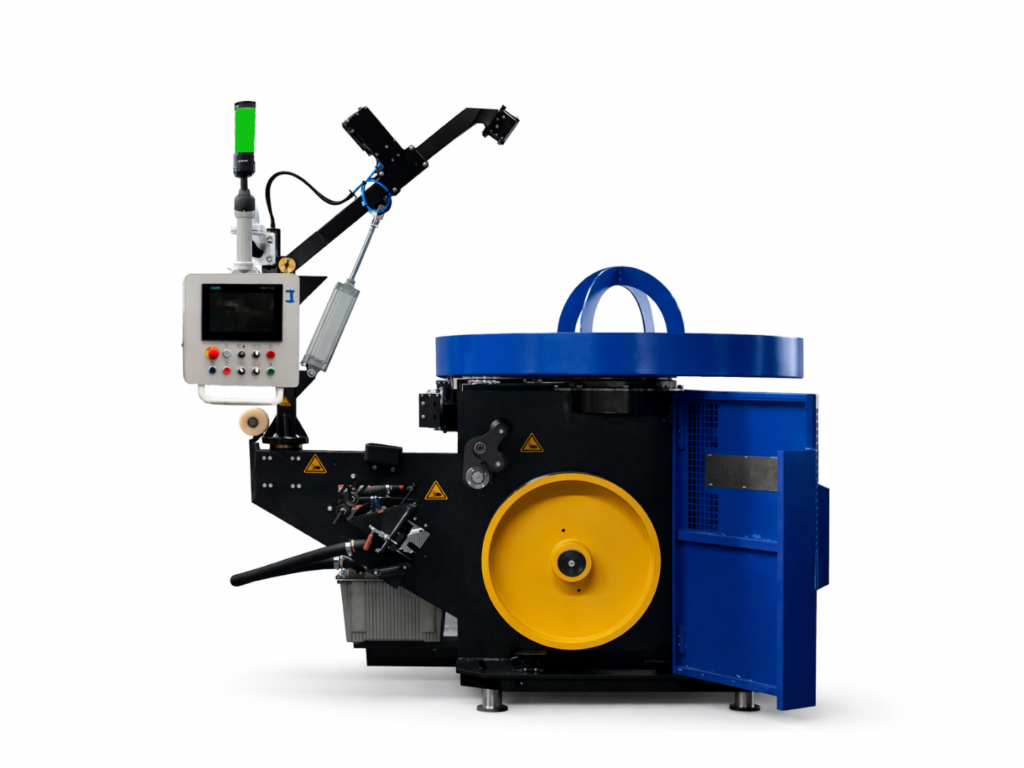

PRO-Series

The PRO-Series is Jankowski’s standard wire pre-drawing machine and offers a wide range of applications for different wire processes thanks to selectable drawing capstan diameters from 600 mm to 1300 mm.

Features of our wire drawing machines

Energy efficient

The drive system of our wire drawing machines is designed individually according to customer requirements. We pay attention to the use of highly efficient geared motors with their respective components.

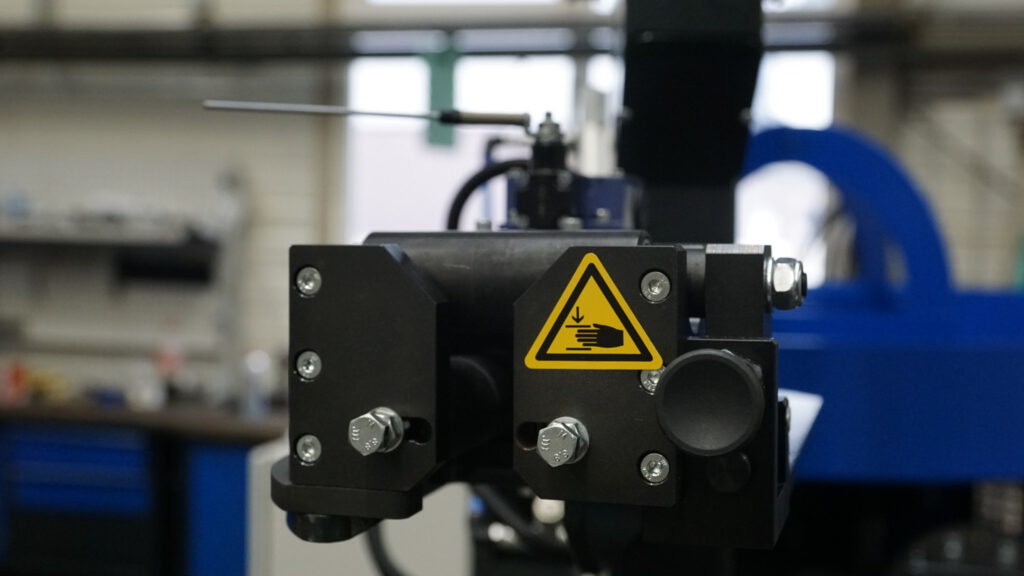

Secure

Our wire drawing machines are all manufactured according to German and European occupational health and safety guidelines. Our highest priority is to sell the customer a user-friendly and safe machine.

Intuitive

With the help of the standard Siemens programmable logic controller and the 10″ touch panel, our wire drawing machines can be operated intuitively. Error messages are shown on the display and can be rectified quickly and safely.

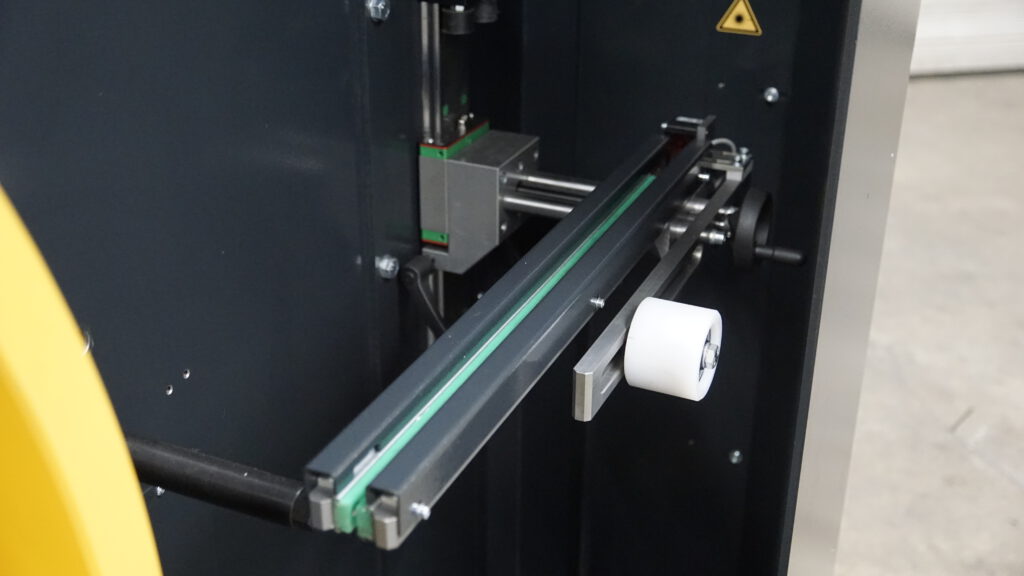

Contactless

Since the use of our patented non-contact wire control, the high restoring forces of the dancer arm and the resulting mechanical intervention in the wire are a thing of the past.

Advantages of wire drawing

1. Technological advantages

- Increased wire strength

- Individual fine adjustment of the wire diameter

- Improved surface quality

- High flexibility by grouping similar wire diameters

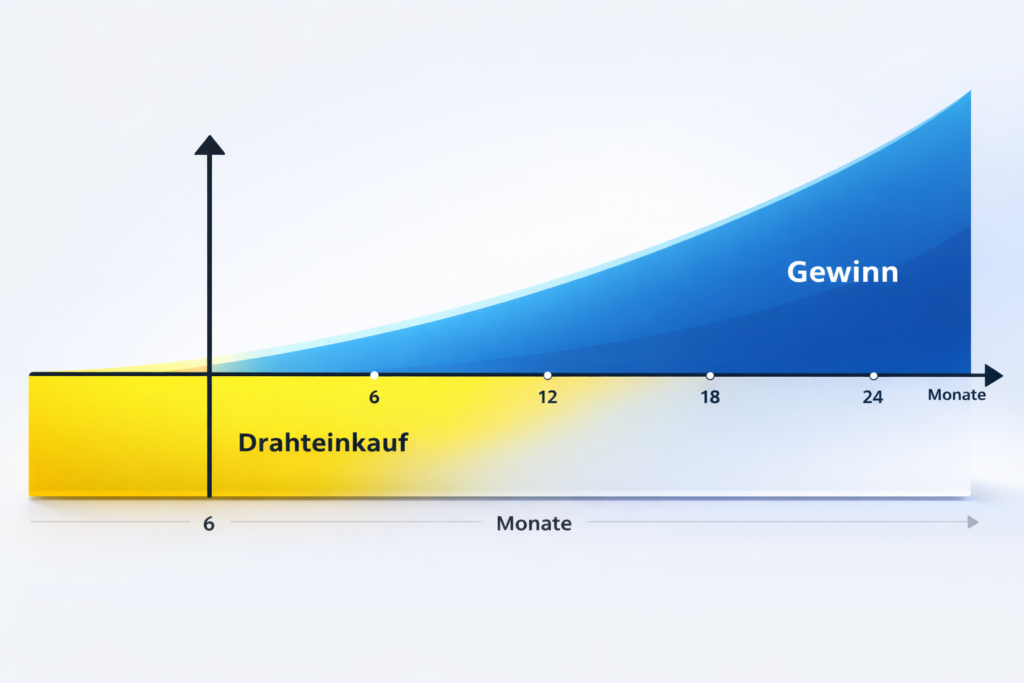

2. Financial advantages

- Cost savings in wire purchasing by grouping similar wire diameters

- Reduced inventory costs through purchasing preferred wire diameters

- Optimized utilization of remaining wire stock

- Reduced investment costs by eliminating the need for expensive motor-driven payoff reels

Jankowski maintenance contracts

Safety at all times. By maintaining your wire drawing machines.

MAINTENANCE BASIC

The BASIC maintenance package includes telephone-based troubleshooting during office hours, online diagnostics via remote service, and annual preventive maintenance measures for your machine. These include a telephone maintenance reminder and a digital service log. Labor and travel costs of the service technician are already included.

MAINTENANCE PREMIUM

In addition to the services included in the BASIC package, the PREMIUM maintenance package provides an extension of the warranty from 12 to 24 months. Customers also benefit from a 10% discount on wear and spare parts, as well as free machine software updates. After 24 months, the contract is automatically converted to the BASIC package.

MAINTENANCE PREMIUM PLUS

The PREMIUM PLUS maintenance package extends the warranty compared to the PREMIUM contract from 24 to a total of 48 months. This not only underlines the high quality of our machines, but also provides customers with maximum security, peace of mind, and investment protection. After 48 months, the contract is transferred to the BASIC package.

You can find more information in our maintenance website:

Contact

Do you have any questions about our wire drawing machines?

Our contact persons are available for a personal conversation.