Wire connection with our

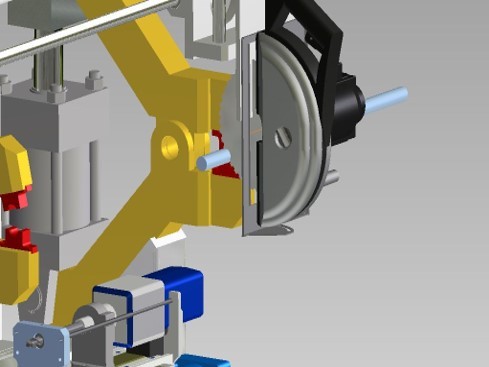

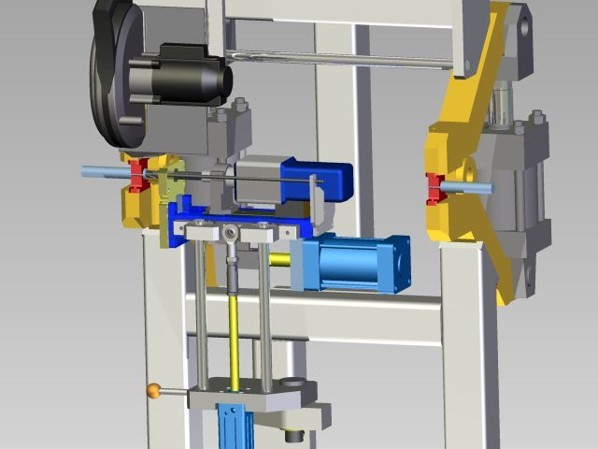

With our “Match-Master” system, wire connections between 12 – 40 mm can be made in less than five minutes. The two wire ends are connected in a positive and non-positive manner, so that a wire reduction of up to 20% is then possible in the drawing process. The resulting seam is visible from the outside, can be measured and the seam can be easily removed from the press using the “idle stroke”.

Benefits of our Match-Master

No set-up times

A coil change can be carried out without set-up times thanks to the wire connection with our Match-Master. The wire connection can be realized in advance in less than five minutes.

Material independent

The wire connection can be carried out independently of the respective material of the wire. Ferrous and non-ferrous metals can be joined here.

Ecologically

By using the Match-Master system, the accumulation of residual wire waste is avoided.

Inexpensive

Due to the simplicity of the Match-Master system, the wire connection can be implemented inexpensively.

Six steps to a secure wire connection

1.

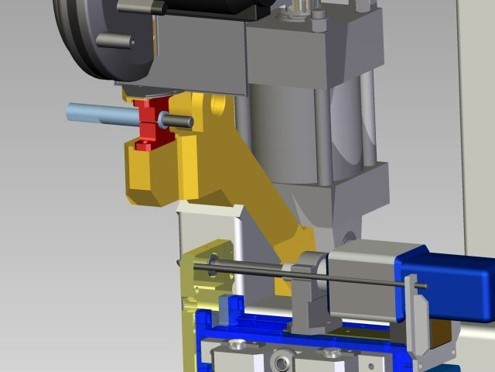

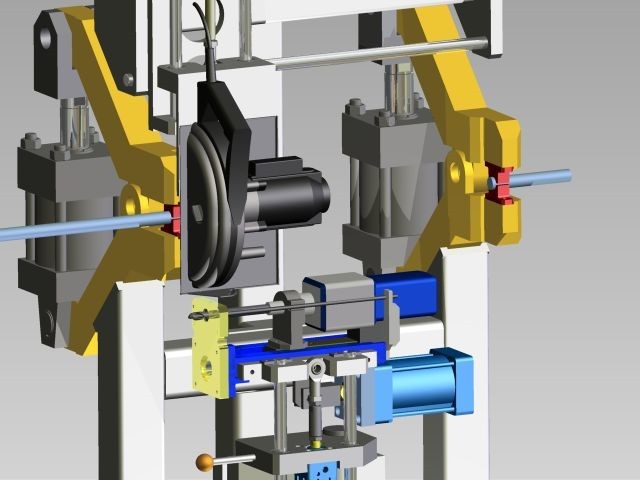

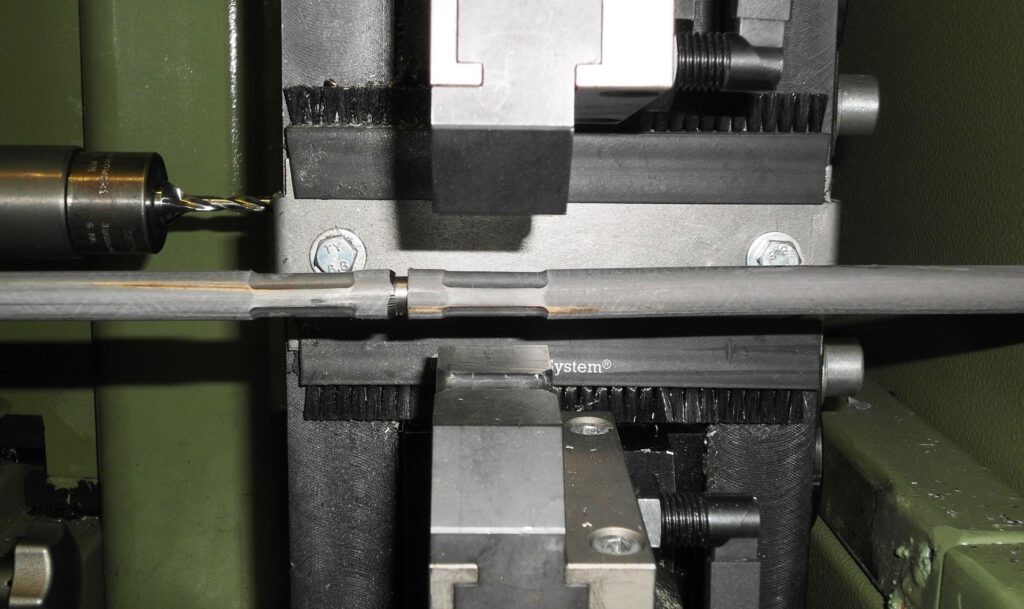

The end of the wire is clamped hydraulically and the wire is sawn off in a defined position.

4.

A defined length is drilled into the second end of the wire, with positioning being carried out pneumatically.

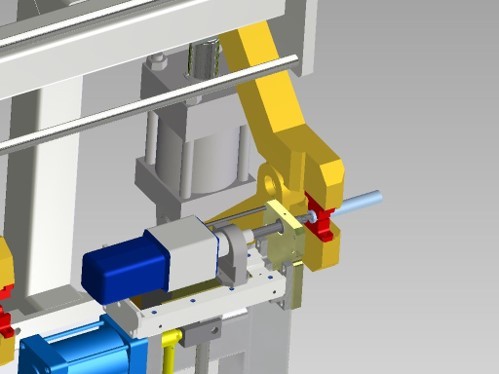

Modular unit

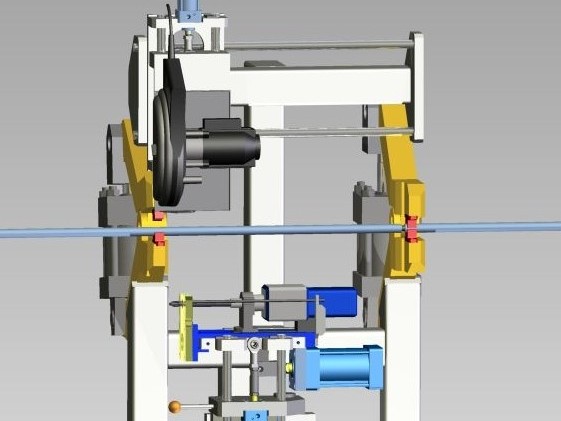

The Match-Master can be integrated as a compact modular unit between the cantilever pay-off and the wire drawing machine with an overall length of approximately 1000 mm. In combination with the wire drawing unit, pointing machine, and cantilever pay-off, the resulting total line length is around six meters and slightly more, enabling a space-optimized and clearly structured line configuration. This ensures efficient use of floor space while providing a high level of process integration and industrial-grade system performance.

Contact

Do you have questions about our Match-Master?

Our contact persons are available for a personal conversation.